Customer testimonial - AMEG Engineering

A smart building and electrical system: AMEG Engineering relies on ALPI to help build one of the world’s most efficient buildings.

Between July 2017 and May 2020, AMEG Engineering was involved in the construction of a building firmly focused on the future

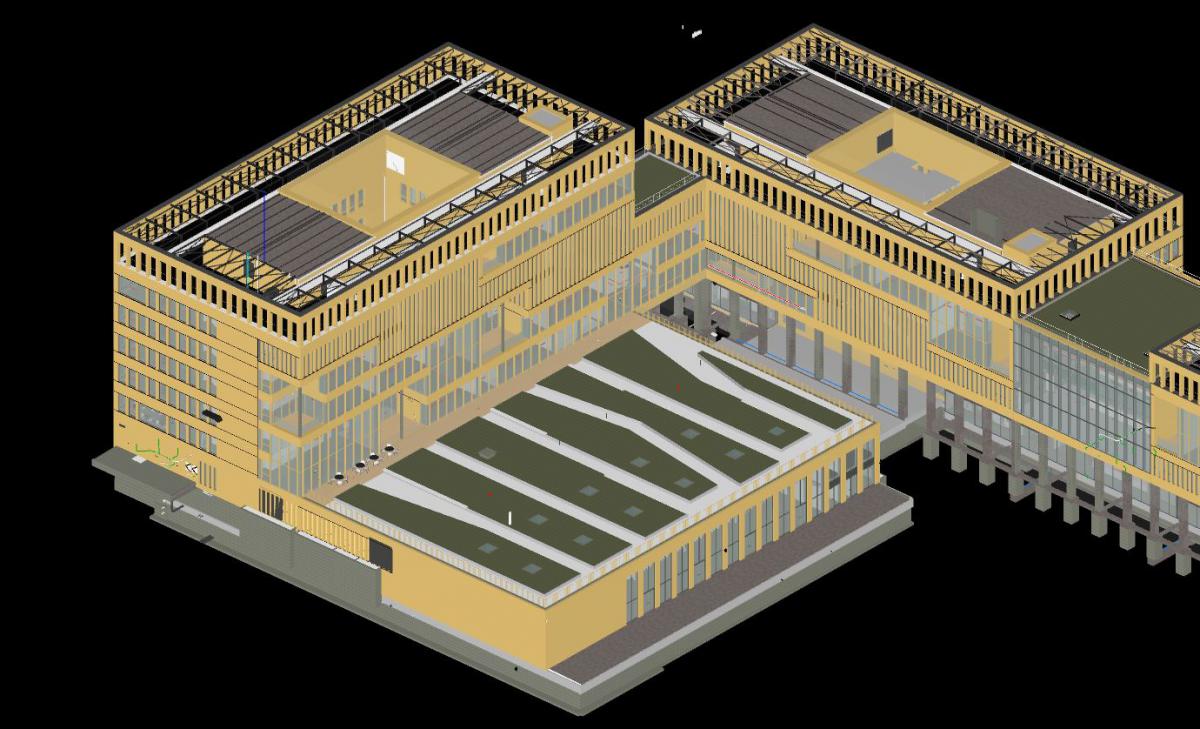

Named IntenCity, this 26,000 m2 showcase of Schneider Electric’s expertise combines cutting-edge technology and sustainable development. A building which is both green and functional, with a tailored electrical system designed specially to address the energy optimisation requirements of Schneider Electric’s EcoStruxure® Building Operation digital solution and the use of green energies.

Georges Gouezin, manager of AMEG Engineering in charge of the building’s electrical design - looks back at this project and the reasons that encouraged him to use Caneco BT, ALPI’s flagship software dedicated to the automated design of low voltage electrical installations.

INTENCITY: A MAJOR ENERGY PROJECT!

- 1 electrical distribution system made up of 2 main LV switchboards

- 1,000 physicalelectricity meters + 3,000 soft electricity meters from multi-business boxes

- 96 electrical switchboards

- 100 km of cables

- 4,000m² of roof-mounted solar panels

- 2 wind turbines

- 1 green energy production solution totalling 970 MWh/year (offsets all the building’s energy expenditure)

- Energy consumed of only 37 kWh/m² per year, all uses combined. 25kwh/m²/year on the office part

- 4 MVA installed electrical power

IntenCity: performance and intelligence benefiting people and the environment

Located in Grenoble's Scientific Peninsula district, IntenCity combines user well-being, digital energy management and sustainable development. Fully connected and networked within its local area, this site is a hub of technology and common sense. Associated with Schneider Electric’s EcoStruxure® Building Operation digital solution, it is more efficient than existing buildings, and consumes much less energy! As proof of this, IntenCity consumes just 37 kWh/m2/year, versus 330 on average for an equivalent tertiary building in Europe. To enhance user comfort and optimise energy consumption as much as possible, it collects over 60,000 pieces of data every two minutes. Continually evolving thanks to the use of predictive data, IntenCity adapts its energy consumption in real-time, avoiding any unnecessary use. Optimisation made possible thanks to four innovative applications linked to the building’s management and control-command systems, space management, energy measurement and control, and energy flexibility.

Currently undergoing LEED Platinum certification, the green building certification program’s highest accolade, IntenCity should have a score of 103 credits - making it the most efficient building in the world!

"All the technical systems (lighting, heating, ventilation, air conditioning, water meter, energy production and storage, etc.) are connected to the EcoStruxure® Building Operation solution. It can manage and optimise consumption in every room. This smart building adapts to the actual number of users and their needs in almost real-time, the weather or even outdoor light levels..."

Georges Gouezin, manager of AMEG Engineering

AMEG Engineering: Schneider Electric’s long-term partner

AMEG Engineering is a Grenoble-based company founded in 2000, with around fifteen engineers and electricians who are experts in high and low voltage, posting €1,500,000 in turnover. It took part in this construction project after being recommended by Schneider Electric. Unsurprisingly, as Schneider Electric and the French electrical engineering company have a long-standing relationship! AMEG has supported it with international projects for over 20 years (Kazakhstan, Madagascar, Brazil, etc.).

"We regularly work on innovative equipment with Schneider Electric’s research centres. Over the years, we have gained a comprehensive insight into their equipment. We have a thorough understanding of all the ranges which could be offered as part of the IntenCity project. Whether high and low voltage distribution, the control-command system or devices. The smart electrical distribution system installed for the IntenCity project is an example of Schneider Electric and AMEG Engineering’s cooperation"

the engineer and manager explains

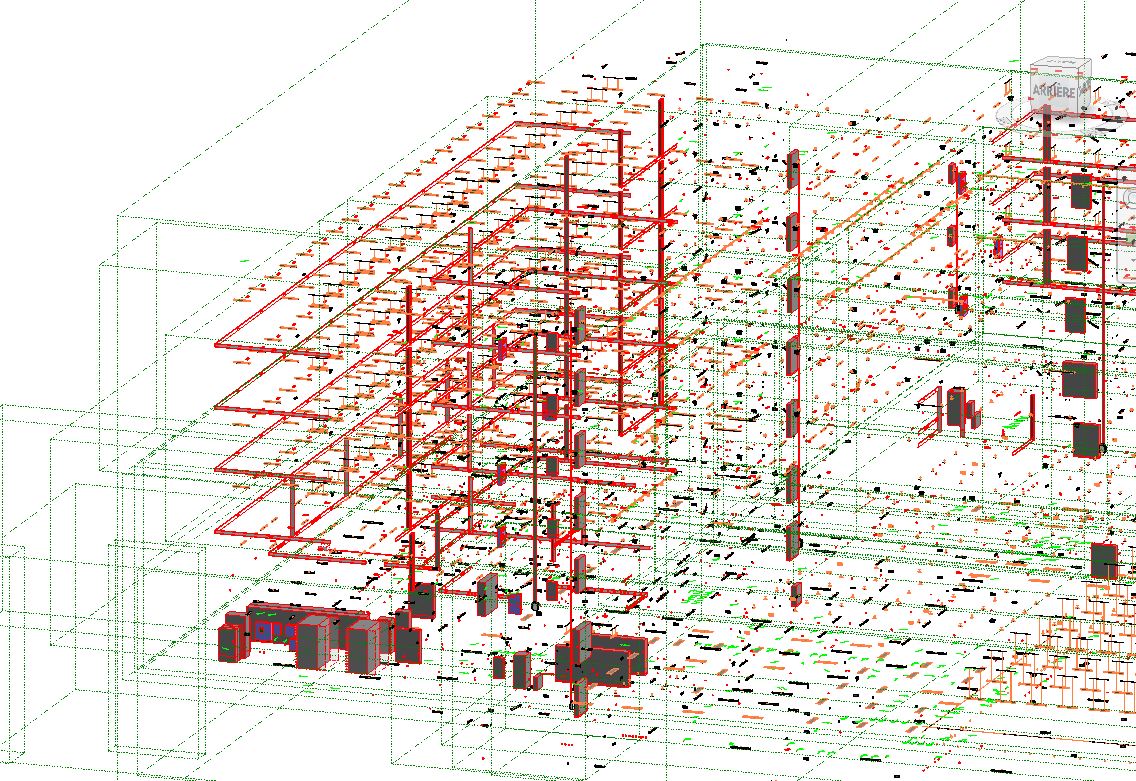

Data and BIM supporting sustainable development

The main challenge for AMEG Engineering was to design electrical network architecture able to report all the data (60,000 items every two minutes) from all the equipment at IntenCity. The destination of this data? The EcoStruxure® Solution Operation, which has managed and optimised IntenCity’s overall energy consumption since project delivery. Another obstacle: the building’s length.

"300 metres in length over 7 floors. The challenge was to guarantee the energy performance of all equipment (solar panels, wind turbines, storage solution as well as internal equipment), whilst limiting the significant and frequent voltage drops in this type of building."

|

|

To achieve this, AMEG Engineering used ALPI's automated low voltage electrical installation design software, Caneco BT.

« Thanks to this software, we have been able to optimise cable sizes whilst ensuring we offer the users a voltage level which meets standards. Based on my 41 years of experience in electrical installation, I think it’s the most advanced low voltage software.»

BIM is now a key part of construction projects. As part of IntenCity, “every socket, every light, every electrical panel was identified in a BIM digital mock-up using a well-defined operating style guide. A development which, with Caneco BT, allows us to devise an electrical network aligned with the building’s smart energy approach,which fully reflects the requirements of the new RE2020 regulations.”

Caneco BT, software which anticipates and guarantees energy performance

In practice, Georges Gouezin and his team of engineers needed to calculate the size of the electrical installations based on the needs of the different IntenCity work packages.

Once the power review was complete, and based on the location of equipment, we created a power tree diagram for the network, and defined powers per zone. Caneco BT was particularly useful for this project! This software allows us to precisely manage usage/bulking factors for devices like electrical panels and main low voltage switchboards. This allowed us to optimise electrical distribution per vertical conduit and per cable.

Another advantage is that this calculation in Caneco BT allowed different project stakeholders to save time and money. How? By allowing Georges Gouezin to realise that the service ducts were undersized.

We were able to anticipate the size of electrical panels and review the initially defined locations. We also optimised the size calculation of transformers and thus optimised their purchase cost and design. Generally speaking, Caneco BT helped us with our distribution choices, but not just that... It helped us to guarantee project feasibility based on expected performance

the AMEG Engineering manager continues

ALPI: technical support always on hand!

The manager of AMEG Engineering knows that he can count on another major asset to ensure his projects make good progress on a daily basis: ALPI’s technical department.

The technical department’s team is always available and played a major role in our use of Caneco BT. It continues to support us so we can make the most of the software, depending on the project. For IntenCity, the technical department was ready to help and explained how to use Caneco BT and optimise the project’s electrical installations. With ALPI, we are self-reliant - but never alone!

About

AMEG Group

AMEG GROUP, industrial engineering company advice and technical assistance

Sites: 12 sites in France

Headquarters: SEYSSINET-PARISET (38)

Seniority: 40 yearsof experience

Workforce: 300 employees

Turnover: 20 millions € in 2020

FR

FR EN

EN DE

DE ES

ES